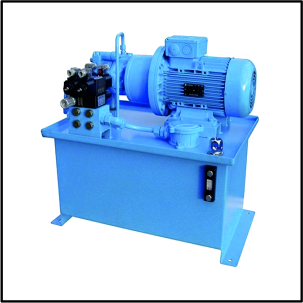

1. Pump Technology: Incorporating high-performance pumps to efficiently convert mechanical power into hydraulic pressure, ensuring a reliable energy source.

2. Reservoir Design: Equipped with well-designed reservoirs for hydraulic fluid storage, facilitating cooling and filtration to maintain fluid cleanliness and system integrity.

3. Control Valves: Precision-engineered control valves enable the regulation of hydraulic fluid flow, allowing for accurate and controlled movement of actuators and machinery.

4. Compact and Modular Design: Designed for space efficiency and ease of integration, with modular components that can be customized to suit specific applications and space constraints.

5. Pressure and Temperature Monitoring: Integrated sensors and gauges for real-time monitoring of hydraulic pressure and temperature, ensuring safe and optimal operating conditions.

6. Reliability and Durability: Built with robust materials and construction to withstand harsh operating environments, ensuring long-term reliability and durability.

7. Noise Reduction: Incorporation of noise reduction features to minimize operational sound levels, contributing to a quieter and more comfortable working environment.

8. Energy Efficiency: Utilization of energy-efficient components and technologies to optimize power consumption and reduce operational costs.

9. Safety Features: Implementation of safety features such as pressure relief valves and emergency shutdown mechanisms to prevent system overloads and ensure operator safety.

10. Remote Control Options: Some advanced units may offer remote control capabilities, allowing operators to manage the hydraulic system from a distance for enhanced convenience and safety.

Hydraulic Power Unit Stations

Description :-

Hydraulic Power Unit Stations are essential systems that generate and distribute hydraulic energy to various machinery and equipment. Consisting of a pump, reservoir, and control valves, these units convert mechanical power into hydraulic pressure, enabling the precise operation of hydraulic systems. They play a crucial role in industries such as manufacturing, construction, and aerospace, providing reliable force and motion control. Designed for efficiency and durability, Hydraulic Power Unit Stations are tailored to meet specific operational requirements, ensuring seamless functionality and optimal performance in diverse applications.

Features of Hydraulic Power Unit Stations